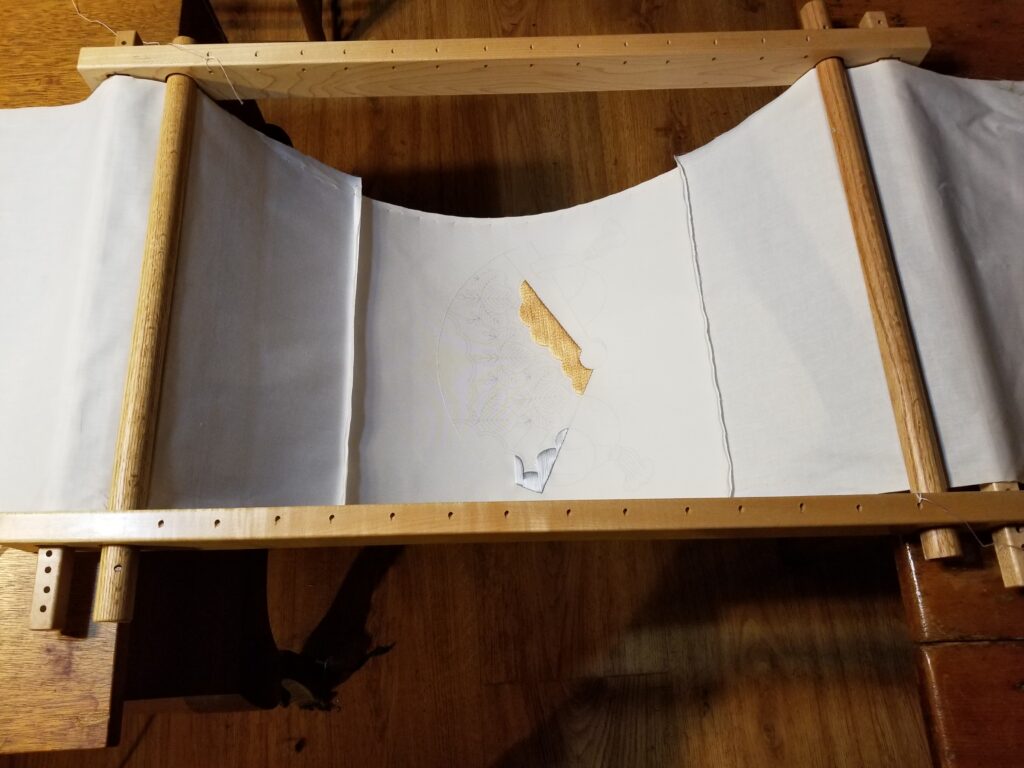

- Set up frame with half of dowel through the holes. The dowels are matched, and have marks identifying pairs. I have the frame sitting on the edge of a pair of tables so the fabric can drape down between the ends.

2. Place fabric over half dowel and slide in other half. Make sure you get the seam between the embroidery fabric and the mounting fabric straight.

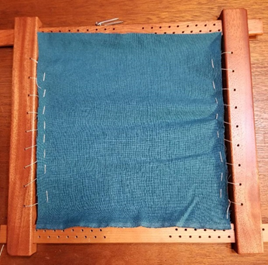

3. Roll the dowels equally towards the ends so the fabric is on the top and secure with a nail through the hole and trapped underneath the stretcher bar. You can see the marks showing the pair of dowels in this picture.

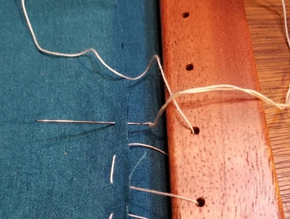

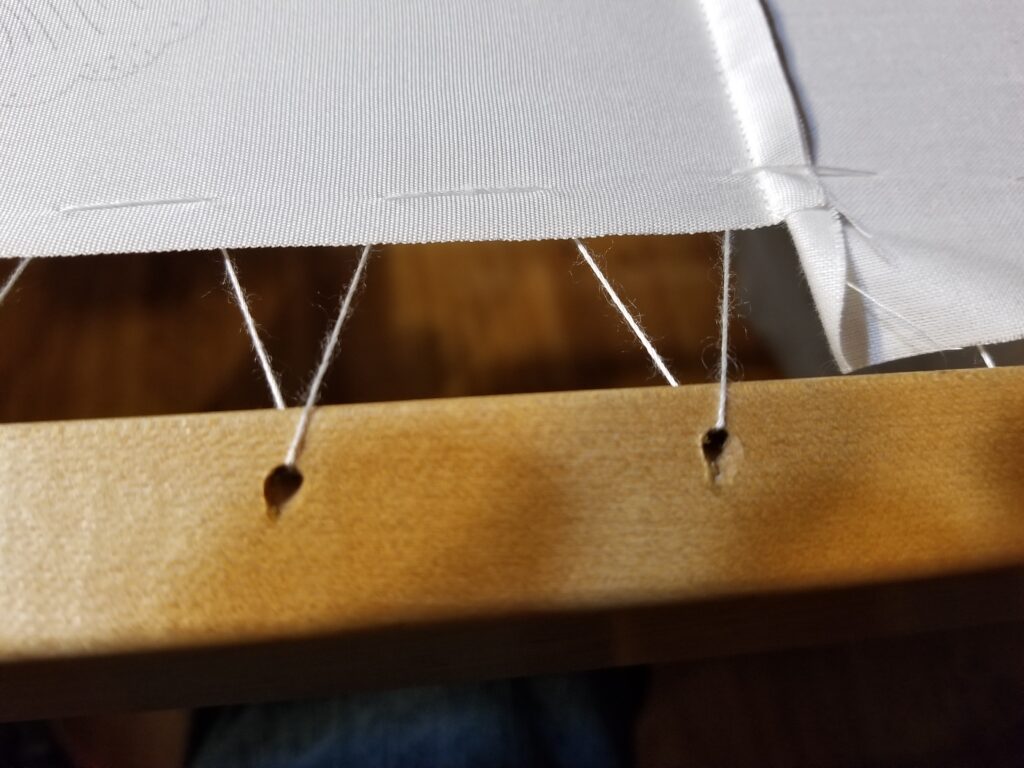

4. Sew fabric to frame. This pattern works very well. Make sure your thread travels along the top of the fabric for about one third to one half the distance between the holes. That will keep the fabric from scalloping.

5. Finally, place pins into the stretcher bars to tighten the fabric. If the holes are not quite in the right place you can wedge a small piece of wood between the pin and the frame. A small piece of a chop stick works well. The fabric should be quite tight.